Some things you never forget.

For me, one is a shale site in Kurdistan — a night where the wind sounded like wolves tearing fabric apart. A maintenance welder, exhausted from a 14-hour shift, lay inside a prefab cabin that leaked water through the seams. Around midnight, he grabbed his boots and slept inside a pickup truck instead.

It wasn’t because he loved cars.

It was because he needed to feel safe enough to close his eyes.

That was also the project where I first saw GS Housing units deployed — the first time camp housing felt engineered for the oilfield, not borrowed from a disaster shelter catalogue.

The Harsh Reality of Oilfield Camps (Where Buildings Go to Die)

People who never step onto field sites often picture clean dorm blocks and neat cafeteria tents.

But most of the real work happens in places like:

deserts — 52°C noon heat, freezing wind after dark

coastal wetlands — humidity that turns bedding sour

winter shale regions — snow deep enough to swallow a boot

plateaus — 3+ hours from the nearest clinic, no backup

These environments destroy materials the way fatigue destroys people.

tents rot

plywood cabins warp

prefab boxes rust in 1–2 seasons

and once relocation begins? — weak housing collapses

The truth — where workers sleep determines whether they return focused, rested, and safe.

Why Housing = Safety (The Part Procurement Often Misses)

Oil work rarely goes wrong because someone forgot a tool.

It goes wrong because someone slept 3 hours and then handled machinery while half-awake.

Workers spend their day:

clearing sand from valves

troubleshooting drilling pipes

working through freezing wind or sunburn heat

Then the shift ends… and what awaits them?

A shared bunk.

A leaking roof.

A room with no door.

Noise that never stops.

It sounds small — until you’ve lived it.

Because in real life, accidents rarely begin with explosions.

They begin the night before — when someone never really slept.

A proper room is not “comfort.”

It is alertness — and alertness is a safety variable.

Where Expandable Container Housing Fits

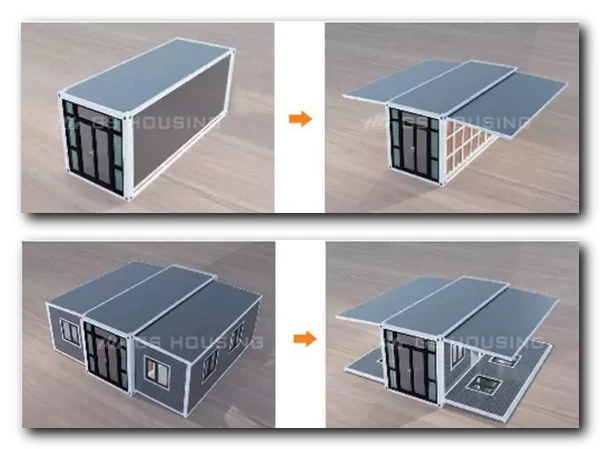

Expandable units seem simple — until you see what they change.

They arrive compact, a steel box.

On-site, walls unfold and lock — and suddenly:

a real room

a raised floor

a door that locks

a window that doesn’t whistle at night

A 40-ft expandable system can transport up to 6 living units.

One truck = 6 beds.

In a camp that must mobilize next week, not next quarter — that difference is everything.

No concrete needed.

A forklift + 4 workers + half a day → people are sleeping indoors tonight.

See what an expandable unit actually looks like

https://gsmobilehouse.com/20ft-expandable-container-house-your-flexible-space-solution/

Not All Expandable Units Are Equal — Engineering Decides Who Sleeps Safe

We learned design through failure — the kind brochures never mention.

Frames bent after the 2nd relocation.

Gutters overflowed in storms.

Weld seams cracked because one worker was tired that day.

So today, non-negotiables look like this:

Governments and NGOs usually think in two stages:

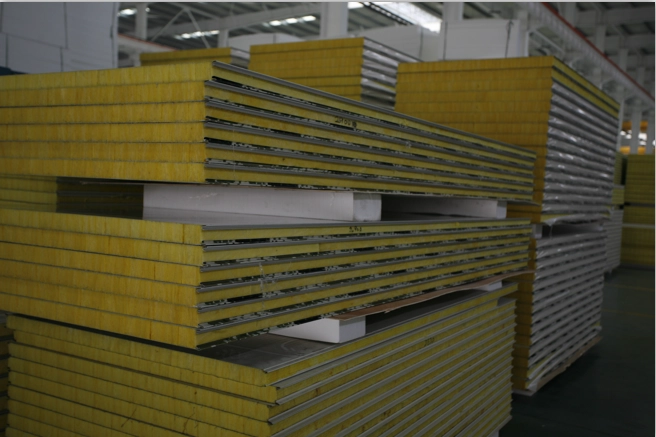

| Component | GS Housing Spec |

|---|---|

| Frame | Galvanized cold-rolled Q235B steel |

| Zinc protection | ≥10 μm, 100 g/㎡ |

| Forming | CNC roller press (beams stay straight) |

| Welding | Automated hydraulic platform + laser cutting |

| ZOuter wall | 60–75 mm sandwich panels |

| Wind | Level 12 |

| Seismic | Level 18 |

| Roof | Extra-wide gutter for extreme rain |

What this feels like at 2 a.m.:

The wall doesn’t shake.

The roof doesn’t hum.

Silence = safety.

How modular camps are really made

https://gsmobilehouse.com/videos/

Oil Camps Are Not Just Beds — They’re Human Places

Governments and NGOs usually think in two stages:

| Stage | Typical Tool |

|---|---|

| Day 1 emergency | Tents |

| Year-5 permanent housing | Concrete buildings |

But what about Month 14? Year 2?

Displacement often lasts years.

Expandable homes exist in the middle — a dignified, movable bridge.

Real-World Example – What Changes When Shelter Changes

At a shale gas site in Inner Mongolia, workers stayed 6 months straight.

Days blended. Morale evaporated.

What changed wasn’t a drilling upgrade — it was space.

Rooms with:

a door that locked

private bathroom

raised floor to dry clothes

insulation that felt like home, not survival

People began eating together again.

They set up a grill corner.

Turnover dropped.

Give workers a room — and they stop feeling like ghosts drifting between shifts.

Mobility — Because Oil Doesn’t Wait for Construction

Oil moves. Camps must follow.

Sometimes the well is dry.

Sometimes approvals shift.

Sometimes a project moves 100 km overnight.

Expandable housing matches that rhythm:

Pack → crane lift → truck load → redeploy

4–8 relocation cycles before maintenance

frames remain aligned

doors still close

units stay sealed

A logistics manager once said:

“These houses understand oil better than we do — they expect to move.”

See real deployments

https://gsmobilehouse.com/projects/

For Procurement — A Field Checklist Worth Stealing

Before signing anything, ask 3 questions:

1.Where will the ground shift?

Soft soil = use pads or steel chassis — otherwise frames twist.

2.Who controls waterproofing?

If sealing depends on “a worker doing a good job,” walk away.

3.Can men sleep without noise waking them?

Not poetic — scientifically tied to accident prevention.

Final Thought — The Most Underrated Safety Investment

Oil is already dangerous.

Housing shouldn’t make it worse.

Expandable units aren’t luxury.

They are how you send workers into the field protected —

and get them back alive and alert.

Give them:

a quiet room

a lock

a hot shower

walls that don’t shake

They’ll give back:

focus

loyalty

safe shifts

Sometimes, the first step toward a safer site…

is simply letting someone sleep well.

Want Real-World ROI Numbers or Layout Plans?

Q: How fast can a camp be set up?

A: One crew can deploy 20–30 units per day. Full settlements in under a week.

Q: Will they rust?

A: Zinc-coated steel + insulated panels → lifespan 10–15+ years with normal maintenance.

Q: Can they move again?

A: Yes. Fold, lift, transport. Reopen. Many camps relocate 3–6 times without damage.

Q: Are they safe for women & children?

A: Yes—lockable doors & rigid walls create a controlled, protected environment.

Closing Thought

If you want cost math, floor plans or deployment timelines:

https://gsmobilehouse.com/contact/