Everyone asks if container homes are strong.

Few ask why some start failing quietly after a few years.

Here’s a confession from someone who’s visited hundreds of sites: the most common container home failure has nothing to do with spectacular storms or collapsing roofs.

It’s quieter. More gradual.

I saw it in a unit in Northern Europe. By year seven, a musty smell had settled in. The wall near the bed felt permanently damp. When we opened it up, the problem wasn’t bad steel or a leaky roof. It was a perfect storm of small decisions: insulation installed without a proper vapor barrier, and corner seams sealed with generic indoor caulk—never meant to survive decades of thermal movement.

The owner kept saying, “But the steel is so thick.”

He was right. And it didn’t matter.

The system around the steel had failed.

That’s the real conversation about container homes durability and long-term container housing. Longevity is engineered. It is not guaranteed by material alone.

It’s Not One Product. It’s Two Very Different Paths.

When people ask about container homes lifespan, they often assume there’s a single answer. There isn’t.

In reality, they’re talking about two completely different categories of steel container housing.

1. The Adapted Cargo Container

This is a retired shipping box turned into a living space. Its DNA is for cargo, not people. Even with modifications, these units often struggle to remain comfortable and problem-free beyond the first decade. Rust-prone original steel, limited thermal breaks, and structural compromises from unreinforced cuts all take their toll.

They can work. But they’re rarely designed with permanent container residence in mind.

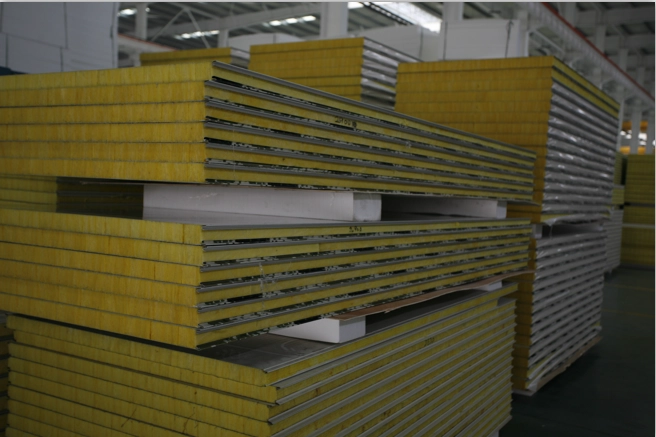

2. The Engineered Residential Unit

This is a home that uses a container-like form as a starting point, not the end point. From day one, it’s designed for people, climate, and long-term use. This category—where we position GS Housing’s engineered residential container systems—is typically built with a 20–30 year lifecycle in mind, often longer with proper care.

You can see how these systems are structured in our expandable container home designs for long-term living(https://gsmobilehouse.com/container-house/)

The difference isn’t magic.

It’s intent, translated into engineering decisions.

That intent is what separates a temporary shelter from true long-term container housing.

Where Durability Is Actually Decided (Hint: Not in the Brochure)

If long-term performance were a symphony, four sections would need to play in harmony. Most failures happen when one goes off key.

Structure: Reinforcement, Not Just Thickness

Yes, steel grade matters. We specify Q235B for its balance of strength and formability. But the real test comes after the cuts are made. Every door and window interrupts the original load path. In temporary units, these cuts are often just framed and welded. In homes meant for permanent use, they must be structurally re-engineered with columns and lintels that redirect loads.

It’s the difference between healing a bone and setting it properly.

Without reinforcement, you don’t see dramatic collapse. You see doors sticking, walls subtly bowing, and alignment drifting over time.

That’s how durability quietly unravels.

This is why we emphasize structural reinforcement design in our residential container projects.

Corrosion: A Plan Beats a Promise

Rust isn’t an “if.” It’s a “when and how.”

A coat of paint is a wish.

Hot-dip galvanizing is a plan.

By immersing the steel frame in molten zinc, you create a sacrificial layer that protects the core steel for decades. This is why bridges and power pylons use it. We combine this with continuous, robotically applied sealants at every seam—because manual sealing is where most long-term leaks are born.

This is the unglamorous side of container homes durability, and it’s where most budget units quietly fail.

You can read more about our galvanized steel corrosion protection system (https://gsmobilehouse.com/20ft-expandable-container-house-your-flexible-space-solution/)here.

Climate: Your Co-Designer, Not Your Enemy

A home in the desert ages differently than one on a tropical coast. Climate is not a backdrop. It’s an active force.

Coastal & Salty: salt accelerates corrosion. We over-spec coatings and use stainless fasteners in critical points.

Humid & Rainy: moisture finds every weakness. Integrated gutter systems and sealed composite panels become non-negotiable.

Hot–Cold Cycles: thermal expansion never rests. Expansion joints, stable insulation, and airtight detailing prevent cracks that invite water.

Durable steel container housing doesn’t fight climate. It speaks its language.

Our teams design units differently for tropical, coastal, and cold-climate projects(https://gsmobilehouse.com/projects/).

Maintenance: The Feature Everyone Ignores

No home is maintenance-free. The durable ones are simply honest about it.

We provide a 10-year container home maintenance roadmap with every unit. It’s not complicated: visual seal checks, clearing drains, and scheduled recoating. Ignoring this is like never changing the oil in a car built for 500,000 miles.

You don’t break durability in one year.

You erode it in ten small ones.

Why Some Container Homes Feel “Flimsy”

There’s an old engineering rule: Cheap. Fast. Durable. Pick two.

Most low-cost relocatable units are optimized for cheap and fast. Durability is the variable that gets traded away.

You see it in:

paint-over-galvanizing that chips at the edges

bolt-together corners that loosen over relocations

basic insulation batts that compress, creating cold bridges and condensation

They weren’t designed to fail.

They were designed for a shorter life.

Using them as a permanent container residence is a category mistake, not bad luck.

The Problems That Don’t Show Up in Year One

Long-term issues rarely announce themselves.

Condensation inside wall cavities.

Insulation slowly losing performance.

Sealants aging under UV and movement.

Tiny leaks that never drip—but never dry.

These are the things that define real container homes lifespan, and they are almost never visible in marketing photos.

This is why system design matters more than material strength.

How to Vet for Real Long-Term Performance

If you want to cut through sales language, ask three questions:

1.After cutting openings, how is structural integrity restored?

2.What is the corrosion protection process, exactly?

3.How is condensation managed inside the wall system?

If someone can’t answer these, they haven’t designed for long life.

The GS Housing Approach: Build the System, Not Just the Shell

Our philosophy is simple: design for year twenty, not just day one.

That’s why we specify zinc density, not just “galvanized.”

Why we use aluminum-zinc interior liners for vapor resistance.

Why our expansion mechanisms are rated for thousands of cycles, not hundreds.

Most of these decisions are invisible.

That’s the point.

This approach runs through everything we build, from worker camps to permanent residential projects. It’s how long-term container housing becomes a realistic option, not a gamble.

Final Thought: Durability Is a Story You Choose

A durable home tells a story of foresight.

It’s written in vapor barriers, zinc coatings, and maintenance logs.

The steel is just the protagonist.

The supporting systems are the plot.

When you evaluate a container home, you’re not just buying a structure. You’re choosing which story you want to live in—the short novel, or the long one.

And in the end, that’s what container homes durability really means.

If you’re planning a long-term project(https://gsmobilehouse.com/contact/), our team can help you evaluate the system—not just the shell.