Picture this: you’re comparing quotes for a container home, and one option is dramatically cheaper than the rest. Same size, same photos, same promises. It feels like a smart find—why pay more for what looks like the same steel box?

Six months later, things feel different. The roof sweats after rain. The room never really cools down in summer. Doors stop closing properly. And suddenly, the container home cost you thought you understood starts showing up in places no one mentioned at the beginning.

This is the gap most buyers don’t see: container homes don’t become expensive at checkout—they become expensive over time. Especially when they’re used as permanent or long-term housing.

The Real Cost of a Container Home Isn’t Just the Box

Most first-time buyers focus on the unit price. But in real-world use, container housing hidden costs tend to fall into a few unavoidable categories.

1. Structure & Reinforcement: Cargo Boxes Aren’t Homes

Many low-cost units start life as retired shipping containers. They were designed to carry goods, stacked and locked in place—not to support years of daily living.

Dents, twisted frames, rusted seams—none of these are obvious in photos. But once windows are cut and loads change, weaknesses show up. Reinforcing a container after delivery is possible, but it’s costly and disruptive.

Manufacturers that design permanent container housing from scratch—rather than modifying cargo boxes—avoid this issue entirely. That’s why factory-built modular systems, like those used in long-term projects by companies such as

GS Housing’s modular container housing solutions(https://gsmobilehouse.com/container-house/), tend to have more predictable long-term performance.

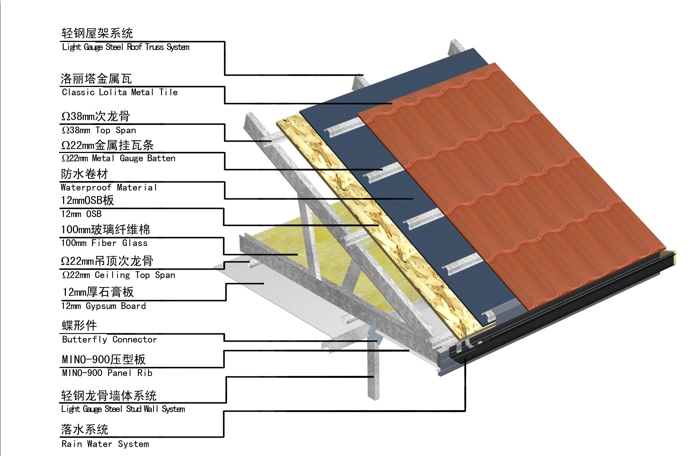

2. Insulation & Energy Bills: Where “Cheap” Starts Costing Monthly

Here’s something buyers only notice after moving in: cheap insulation doesn’t feel cheap at first—it feels fine.

Until the first real summer or winter hits.

In hot regions, the AC runs all day but the room never quite cools down. At night, the walls keep releasing stored heat, like a car that’s been sitting in the sun. In colder climates, you turn the heater off for an hour and the temperature drops fast.

This is where container home cost quietly shifts from a one-time purchase to a monthly drain. Many owners accept $200–$300 higher energy bills as “normal,” without realizing it’s a design issue, not the climate.

Good insulation and proper thermal breaks don’t look impressive on day one—but six months in, when the bills stay steady and condensation never appears, that’s when they pay you back.

3. Waterproofing & Corrosion: Small Shortcuts, Big Repairs

Steel doesn’t forgive water.

Cheap units often skip industrial-level corrosion protection and rely on surface coatings that look fine until humidity, salt air, or standing water get involved. Roofs without proper slope or drainage quietly collect water. Window seals fail first, then rust creeps in.

In long-term use, these aren’t cosmetic problems. They turn into structural repairs that cost more than the savings that justified the cheap unit in the first place.

4. Transport & Installation: The Costs Nobody Puts on the Quote

A container home isn’t furniture. Getting it to site—and setting it correctly—comes with real logistics:

Oversized transport permits

Crane access and lifting radius

Site preparation so the frame doesn’t twist

Foundation alignment to prevent long-term stress

Low quotes often exclude these. That’s why buyers are surprised by “unexpected” bills that weren’t really unexpected—just unlisted.

5. Installation & Foundations: “Drop & Go” Rarely Works Long-Term

Placing a container directly on the ground might look fine on day one. Two rainy seasons later, doors stick, floors slope, and seams open up.

For permanent container housing, proper foundations aren’t optional—they’re what keep everything square, dry, and compliant over time.

Three Common Myths That Quietly Inflate Container Home Risks

Myth 1: “I’ll buy cheap now and upgrade later”

Retrofitting insulation, wiring, or structure after delivery usually costs two to three times more than doing it right in the factory. It’s like renovating a house while living in it—possible, but rarely economical.

Myth 2: “Temporary units can be used permanently”

Many low-cost units are classified as temporary structures. Using them as permanent homes can mean inspection issues, insurance gaps, or forced upgrades later—classic container home risks that show up only after you’ve settled in.

Myth 3: “If it looks solid, certifications don’t really matter”

When something goes wrong, inspectors and insurers don’t ask how it looked—they ask how it was tested.

Without proper reports, responsibility becomes blurry. No insurance coverage. No installer accountability. Just a problem that’s suddenly yours to solve.

Certifications don’t make a home stronger by magic. They simply prove that the hard questions were asked before you moved in.

Cheap vs. Long-Term: Where the Real Cost Gap Comes From

The price difference between cheap and long-term container housing usually isn’t the steel itself—it’s whether the unit was designed for years of use or just quick delivery.

Purpose-built systems, like those used in long-term worker housing and infrastructure projects byGS Housing(https://gsmobilehouse.com/), focus less on headline price and more on predictable performance. That’s why they’re chosen for environments where failure isn’t an option.

Final Thought: Cost Isn’t About Being Cheap—It’s About Being Honest

A container home can absolutely be affordable, durable, and comfortable. But only if the price reflects how you actually plan to live in it.

The biggest mistake isn’t spending too much upfront—it’s assuming a low quote means low risk. In reality, most permanent container housing cost gaps show up later, disguised as “unexpected” fixes that were visible from the start.

If you’re comparing options now, slow down just enough to ask better questions:

What’s designed for long-term use? What’s been tested? What problems will I still be paying for two years from now?

Clear answers usually matter more than low numbers. And when a supplier is willing to walk through those details—without rushing you—that’s often the first sign you’re looking at something built to last, not just to sell.

If you’re still weighing options, you don’t need a sales pitch—you need clarity. A quick technical conversation can often reveal whether a container home is designed for short-term placement or truly ready for years of living.

If you want to sanity-check a quote, compare lifecycle costs, or simply understand what’s included (and what isn’t), you can contact the GS Housing team (https://gsmobilehouse.com/contact/)for a straightforward discussion. No pressure—just a clearer picture before decisions get expensive.