If you’re a global distributor in modular or prefabricated housing, your biggest risk isn’t demand. It’s choosing the wrong expandable container house manufacturer.

Pick the wrong partner, and you inherit their delays, their quality problems, and their communication gaps. I’ve seen otherwise solid distribution businesses lose key clients—and entire regions—because one supplier couldn’t deliver what they promised.

This isn’t another surface-level checklist. It’s a practical, field-tested framework for choosing an expandable container house factory or supplier that won’t damage your margins or your reputation.

The 3 Most Common Mistakes When Choosing an Expandable Container House Supplier

Most first-time distributors fall into at least one of these. Knowing them upfront saves you months of pain.

Trap 1: The Trading Company Mirage (Middleman Risk)

Trading companies are easy to work with on paper. Fast replies. Clean websites. Friendly sales reps.

But here’s the reality: they don’t build anything.

They source from factories you’ll never see, add their markup, and sit between you and production. When a client reports a leaking roof or a folding system issue, you’re stuck relaying messages instead of solving problems.

Working directly with a true expandable container house factory removes this friction. You control pricing, communicate with engineers directly, and fix issues at the root instead of guessing.

Trap 2: “Brochure Beauty” Without Real Production Capacity

A polished gallery doesn’t equal manufacturing strength.

Many so-called expandable container house suppliers can handle small sample orders but collapse when faced with a 100- or 150-unit project. Suddenly it’s “capacity adjustments” or “unexpected delays.”

By the time you realize it, your project timeline is already broken—and your client won’t forget that.

A reliable manufacturer proves capability with production floors, not photos.

Trap 3: Unrealistic Delivery Promises

Missed delivery dates do more damage than price disputes.

Some suppliers promise aggressive lead times just to secure orders. Once production starts, material shortages and poor planning push everything back. Your shipment sits at port. Your client’s site is idle. And you’re the one answering angry calls.

Professional manufacturers give conservative timelines—and then hit them.

How Global Distributors Should Evaluate an Expandable Container House Factory

Once you’ve avoided the traps, these are the non-negotiables. This is where real partners separate themselves from risky suppliers.

1. Factory Scale and Verifiable Production Capacity

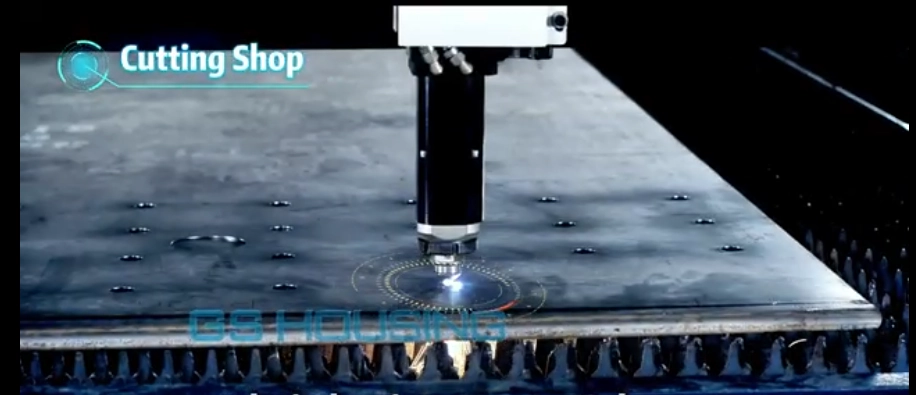

You’re not looking for a workshop. You need a factory with dedicated lines for steel processing, assembly, finishing, and quality inspection.(https://gsmobilehouse.com/videos/)

Ask for a live or recorded walkthrough—not marketing clips. Can they show 100+ identical units being built simultaneously? If your target market is project supply, their output must match that ambition.

Capacity that only works “on paper” doesn’t help you win tenders.

2. Export Experience Aligned With Your Target Market

Export experience is not generic.

A factory shipping regularly to Europe understands CE compliance and documentation workflows. Middle East experience means familiarity with SASO and regional project requirements. Australia has its own structural and safety expectations.

A manufacturer who has already shipped to your market saves you from customs delays, rejected cargo, and costly rework.

3. Standardization That Ensures Consistent Quality

Consistency matters more than one perfect sample.

Ask about their QC process. Is there a checklist at every stage—raw materials, welding, painting, final assembly? Do they keep waterproofing and load-bearing test records?

Standardization ensures every unit you deliver meets the same spec—not just the first batch.

4. Genuine OEM/ODM Customization Capability

Real projects aren’t one-size-fits-all.

Cold regions require upgraded insulation. Hot climates need ventilation and HVAC adaptations. Some clients need solar-ready wiring or modified layouts.

A true expandable container house manufacturer engineers solutions. A catalog-only supplier limits your ability to win higher-value contracts.

Expandable Container House Quality Standards That Actually Matter

Quality failures always land on the distributor. These four checks protect you.

1. Structural Steel: Built to Last or Built to Rust?

The frame is everything.

Hot-dip galvanized steel is the industry baseline for corrosion resistance. Ask for galvanizing reports and material certificates. Painted or thin steel may look fine initially, but rust quickly compromises structure—especially in coastal or humid regions.

2. Folding System Reliability

The expansion mechanism is the core of the product.

Professional factories cycle-test folding systems repeatedly before shipment. Ask how many open-close cycles they test and request a demonstration video. Smooth operation and secure locking are non-negotiable.

If a supplier hesitates on this question, that’s a warning sign.

3. Weather Resistance: Waterproofing and Wind Performance

Your units will face real environments, not showroom conditions.

Ask for:

Waterproofing test standards and results

Wind load or structural calculation reports for high-wind regions

A reliable factory provides these documents without deflection.

4. Long-Term Durability and Serviceability

Expandable container houses are long-term assets.

Ask about expected service life, spare-part availability, and ease of maintenance. A manufacturer confident in their build quality will back it with a clear structural warranty (typically five years or more).

Why Working Directly With an Expandable Container House Manufacturer Matters

Working directly with a factory isn’t just about cutting out middlemen—it’s the foundation of a stable, profitable distribution business, with three unbeatable advantages:

- Better cost control: No trading company markups, you get factory-direct wholesale prices. This keeps your gross margins steady and gives you more flexibility in local pricing.

- Faster project response: Urgent orders or custom tweaks can be confirmed directly with the engineering team—no delayed message relay. You’ll meet tight project deadlines and impress key clients.

- Controllable after-sales: After-sales support, spare parts supply and technical guidance all come straight from the factory. You won’t be stuck dealing with unresponsive middlemen when clients have problems.

Why Many Global Distributors End Up Working With GS Housing

After a few years in this business, most distributors stop chasing “the cheapest supplier” and start looking for something more boring—but safer.

Fctories like GS Housing(https://gsmobilehouse.com/) tend to show up at that stage. Not because of flashy marketing, but because their operating style fits how real distribution businesses work, with three core strengths that distributors value most:

Factory strengths: Stable dedicated production lines, verifiable bulk output capacity, and mature teams with rich overseas project experience—no more unexpected delivery delays or capacity gaps.

Product maturity: Strict standardized QC processes, tested folding/waterproof/wind-resistant systems, and consistent product specs. Every batch you receive is as reliable as the first.

Cooperation cases(https://gsmobilehouse.com/projects/vanuatu-expandable-container-camp/): (to be added later: overseas mining camp project /emergency housing project /infrastructure worker camp project with 100+ units, for distributors to reference)

How to Pick a RHow to Get Factory Quotes and Evaluate Cooperation Term

Ready to pick a reliable expandable container house manufacturer without costly risks? Take direct action now—no more guessing, no more traps:

- Claim your free Manufacturer Evaluation Scorecard (based on all the checks above) to compare suppliers side by side clearly, no fluff.

- Contact GS Housing directly to get exclusive distributor wholesale quotes, factory tour arrangements, and detailed cooperation terms (including MOQ, delivery lead time and after-sales support).

Directly connect with the source factory—no middlemen, no vague promises, just transparent communication and stable support to help you grow your distribution business steadily.

Thinking About Your Next Move?If you’d like a copy of the scorecard, or want to walk through how we handle overseas distributor projects in detail, reach out and ask. No pressure, no hard sell—just the practical information you need before signing anything.