Why Expandable Home Durability After Multiple Relocations Matters

When evaluating expandable home durability after multiple relocations, the biggest risk isn’t storms—it’s cutting corners in engineering and installation.Last winter in Hamburg, a cabin door wouldn’t close. The problem wasn’t dramatic—no storm, no fire—just soft ground nobody compacted.The danger isn’t storms—it’s believing a temporary fix will last another season. But that small lean becomes a draft, then a leak, then a frame that refuses to realign. I’ve watched this same story unfold in Spain, Montana, and once on a site where goats literally walked across the “foundation.”

Most viral failure headlines blame prefab itself:

“Expandable house collapses in storm.”

But the truth is usually quieter:

Designed for Instagram, not weather

Moved three times, never re-anchored

Built fast for ribbon cutting, not year five

What Harms Expandable Home Durability After Repeated Moves

Strip away the marketing, and the dangers I’ve seen are embarrassingly consistent.

1.Built for First Impression, Not Year Three

Some models look great on arrival…

This is why expandable home durability after multiple relocations depends on frame design, not just initial looks.

until the first relocation:

doors jam

seams stretch

water tracks its way inside

Because the frame was never meant to move again.

2.Steel So Thin You Could dent it with a shoulder

I once saw a “budget cabin” where the wall flexed like cereal box cardboard.

If a structure reacts like packaging foam—it’s not shelter

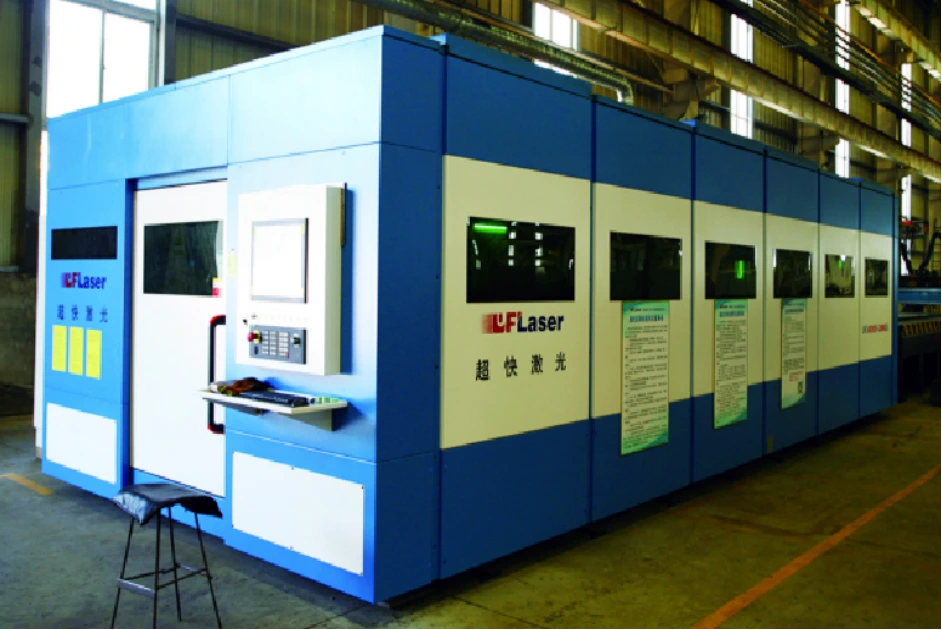

See what industrial-grade framing actually looks like →

https://gsmobilehouse.com/container-house/

3.Weather Sealing That Depends on Someone’s Mood

If waterproofing requires a worker to “do a good caulk job”…

that’s gambling, not engineering.

4.When Homes Fail, It’s Often the Ground

Engineers say a sentence most owners ignore:

“No structure is stronger than the soil beneath it.”

Ask our team for ground-prep drawings—free.(https://gsmobilehouse.com/contact/)

Place a unit on loose dirt or grass → slow twist → misalignment → complaints.

People then blame “poor construction,” while standing on soil that sinks like sponge cake.

What Makes Safe, Durable Expandable Homes for Repeated Moves

For expandable homes, safety = repeatability:

same frame strength, every batch

same weld quality, every joint

same weather sealing, factory-applied

same performance even after the fifth relocation

It should feel like a building that folds,

not a tent that pretends to be a building.

Where GS Housing Fits (Short, Factual – Not Sales Fluff)

Most innovations came from seeing where cheap prefab fails:

frames bending on 2nd move

gutters overflowing during heavy rain

welding alignment changing by worker skill level

Our approach directly solves the issues that ruin expandable home durability after repeated moves—consistent steel quality, automated welding, and factory-sealed weatherproofing.

So—engineering changed.

See a live expandable camp project →Vanuatu Scalable Container Camp Project(https://gsmobilehouse.com/projects/vanuatu-expandable-container-camp/)

A Quiet Real-World Example

Most innovations came from seeing where cheap prefab fails:

frames bending on 2nd move

gutters overflowing during heavy rain

welding alignment changing by worker skill level

So—engineering changed.

| Component | GS Housing Approach |

|---|---|

| Frame | Galvanised cold-rolled Q235B steel |

| Zinc protection | ≥10 μm, zinc ≥ 100 g/㎡ |

| Forming | CNC roller press – beams always straight |

| Welding | Automatic hydraulic platform + laser cutting |

| Outer wall | 60–75 mm sandwich panel |

| Inner wall | 0.45 mm pure flat aluminized-zinc steel |

| Wind rating | Level 12 storm-rated |

| Seismic | Level 8 performance |

| Roof | Extra-wide integrated gutter for extreme rainfall |

See a live expandable camp project →Vanuatu Scalable Container Camp Project(https://gsmobilehouse.com/projects/vanuatu-expandable-container-camp/)

If You’re Installing One, Don’t Skip This

Here are the only rules I repeat, even if it costs a sale:

- If the soil moves, the house moves.

Compact it or add pads.

If the wind is strong, anchor it.

Treat it like a boat, not a suitcase.

3.If there are no written test numbers—walk away.

Expandable ≠ exempt from physics.

It is still a building. Treat it like one.

Final Word

Are expandable homes safe?

They can be—when engineered, tested, and installed like buildings.

They aren’t—when someone says,

“eh, it only needs to last until opening day.”

The smarter question isn’t:

“Can it expand?”

It’s:

“Will it still stand after the fifth move?”

FAQ

Q1. Do expandable homes collapse in storms?

Only if they aren’t anchored. Rated steel and proper wind anchoring prevent movement.

Q2. How often can you relocate one before it weakens?

Well-built units should handle multiple relocations without frame fatigue—GS Housing units retain alignment after 5+ moves.

Q3. Do they require foundations?

Not concrete necessarily—compacted soil or steel pads are enough, if properly leveled.

Q4. Are expandable homes allowed for permanent use in Europe?

Local zoning applies. Many clients use them for worker housing, clinics, or tourism cabins—permits vary by country.

Q5. Are expandable homes more cost-effective than traditional K-type after multiple relocations?

Absolutely—here’s why: K-type homes rack up costs fast with repeated moves (20+ hours/month in repairs, 50% higher energy bills, replacement after 3-4 relocations). Well-engineered expandable units (like GS Housing’s) have low, predictable maintenance (mostly filters/bulbs) and no performance decay—saving you money in the long run, even with 5+ move

If you want numbers—wind load, move cycles, or cost curve after year three—ask. We’ll answer like engineers, not marketers. → https://gsmobilehouse.com/contact/