When people talk about turning a shipping container into a permanent home, the conversation usually starts with design.

Big windows.

Open kitchens.

Minimalist interiors.

Almost nobody starts with permits.

Until something goes wrong.

Until a project gets stopped.

Until an inspector says, “This isn’t approved.”

Until a family realizes they can’t legally live in the space they already paid for.

That’s the hard truth about permanent container housing: if approval and building codes aren’t handled properly, the home doesn’t exist — at least not in the eyes of the law. Manufacturers with real project experience, like GS Housing’s modular housing team (https://gsmobilehouse.com/company-history/), design their units around these realities from the beginning.

And no amount of creativity can fix that later.

This is where container homes approval, container homes building codes, and permanent container housing compliance stop being “technical details” and start becoming the foundation of the entire project.

Why Permanent Container Homes Can’t Skip Approval & Codes

A shipping container is strong. That’s not the issue.

The issue is that it was designed to carry cargo — not people, not wiring, not bathrooms, not insulation, and not decades of daily living.

Once you cut openings, add windows, run electrical lines, and install plumbing, you’re no longer dealing with a “container.”

You’re dealing with a building.

And buildings come with rules.

Building codes exist for one simple reason: to make sure people don’t get hurt, sick, or displaced because a structure failed.

For container homes, regulators pay close attention to things like:

- how heat and cold are controlled inside steel spaces

- whether the structure stays stable after doors and windows are cut

- how fire spreads inside a metal box

- where water goes when it rains for days

That’s why container homes approval isn’t about slowing projects down.

It’s about proving the space is safe enough for someone to actually live in.

Manufacturers with real project experience, like GS Housing, design their units around these realities from the beginning — not as an afterthought. Because once a container is built wrong, fixing it later is painful, expensive, and sometimes impossible.

How Container Homes Are Usually Classified (and Why It Matters)

This part confuses a lot of buyers.

People assume container homes are either “allowed” or “not allowed.”

In reality, most regions don’t think in those terms. They think in categories.

And the category you fall into determines whether permanent living is even possible.

- Temporary Structures

This is the easiest box to get into — and the hardest to live with long term.

Temporary classification is common for site offices, worker camps, or emergency housing.

Approvals are faster, but there’s always an expiration date.

You can live there “for now.”

You just can’t stay.

Trying to convert a temporary structure into a permanent residence later usually means starting the approval process all over again — with stricter rules.

- Modular or Factory-Built Housing

This is where permanent container homes start to make sense.

Think of it like this:

A temporary structure is like a food truck.

Modular housing is like a restaurant chain.

Both serve food.

But one is designed to move and disappear, and the other is designed to be inspected, standardized, and trusted.

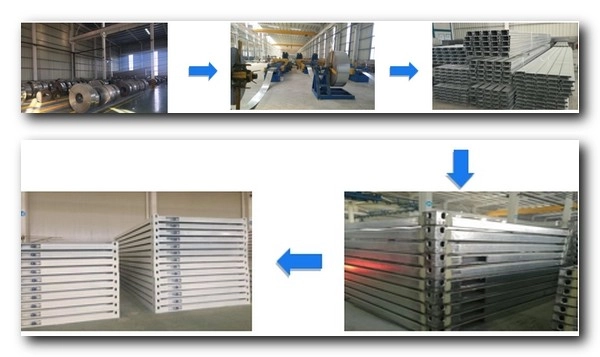

When a container home is built in a factory, with consistent materials and controlled welding, many authorities are more willing to treat it as modular housing — the same logic behind factory-built expandable container homes

(https://gsmobilehouse.com/container-house/).

This is why companies like GS Housing put so much emphasis on factory production, structural testing, and documentation. It’s not about sounding professional. It’s about fitting into a category that regulators already understand.

If your container home looks like a one-off experiment, it will be treated like one.

If it looks like a standardized housing system, the conversation changes.

- Custom Residential Buildings

When multiple containers are combined, heavily modified, or permanently fixed to foundations, they may be treated like any other custom house.

That comes with full code requirements — and full residential rights.

It’s more work.

But it’s also the clearest path to permanent legal status.

What Inspectors Actually Care About

When authorities review permanent container housing compliance, they usually don’t get emotional about design. They focus on four practical things.

Structure

Once you cut a hole in a steel box, you weaken it. That’s physics.

Inspectors want to know:

- Was the frame reinforced?

- Is the steel protected from rust?

- Can it handle wind, snow, or earthquakes in this area?

Using galvanized steel like Q235B and proper reinforcement is not a “premium feature.”

It’s the baseline.

Fire

Steel doesn’t burn — but everything inside it can.

This is why fireproof container homes matter.

Fire-rated panels, safe wiring routes, proper ventilation — these are not negotiable for approval.

If materials don’t have certification, inspectors will ask questions.

And they won’t go away.

Water

Steel + water = long-term problems.

Leaks, condensation, mold — these are common in poorly built units.

That’s why waterproof container housing needs proper sealing, drainage design, and raised floors. Not just silicone and hope.

Insulation

Without insulation, a container is an oven in summer and a fridge in winter.

Inspectors look for:

- real insulation values

- vapor barriers

- airtight construction

This is where insulated container homes either pass or fail.

There is no shortcut here.

Why Approval Gets Stuck (More Often Than People Expect)

Most approval problems don’t come from strict governments.

They come from unprepared projects.

The biggest issues are surprisingly consistent:

- drawings that don’t match the actual structure

- missing test reports

- designs that ignore residential standards

- projects built before approval is even requested

Trying to “fix” compliance after construction is like trying to add seatbelts after a crash. Technically possible. Practically painful.

This is why experienced suppliers push so hard to prepare documents early.

GS Housing, for example, builds their compliance packages alongside the unit — structural data, fire ratings, layout drawings — so nothing has to be guessed later.

It’s not flashy.

It just works.

The Rule That Saves the Most Money: Design for Permanence

If you think there’s even a chance a container home will be used long term, design it as a permanent residence from day one.

That means:

- checking local classification rules early

- choosing certified materials, not just cheap ones

- working with teams that understand container housing from the start — such as GS Housing’s project consulting team (https://gsmobilehouse.com/contact/) — often saves months of back-and-forth later.

Permanent container housing compliance is not something you “add.”

It’s something you build around.

Projects that respect this usually move smoothly.

Projects that ignore it usually stall.

A Practical Urban Application Example

(expandable container homes case study, urban modular housing)

In a mid-sized European redevelopment zone, planners faced a common problem: a 12-month gap between site clearance and permanent construction, with over 150 workers needing compliant accommodation.

Instead of traditional temporary buildings, the project adopted expandable container units.

Deployment finished in weeks, not months.

Costs were significantly lower than on-site builds, mainly due to reduced labor and logistics.

After the project, most units were relocated to a student housing pilot instead of being dismantled.

This kind of outcome isn’t unusual.

From workforce housing to temporary community hubs, expandable systems perform well where adaptability matters more than custom finishes.

They don’t eliminate complexity — they manage it.

Final Thought

At some point, every container home project stops being about steel, panels, or floor plans.

It becomes about one simple question:

“Can we really live here without worrying?”

Not worrying about inspections.

Not worrying about whether the permit will be pulled.

Not worrying about whether someone will knock on the door and say, “This isn’t approved.”

That’s what compliance really gives you.

Not paperwork. Not stamps.

Peace of mind.

Permanent container housing only works when it feels stable — legally, structurally, and emotionally. When people can stop thinking about the building and start thinking about life inside it.

That’s why approval and building codes are not a formality. They are part of the home.

And that’s also why experienced manufacturers like GS Housing focus so heavily on compliance from the design stage. Not because it looks good in brochures, but because they’ve seen what happens when it’s ignored.

If there’s one thing years of projects teach you, it’s this:

Shortcuts show up later.

And they’re always more expensive.

Build it right.

Approve it properly.

Then live in it without looking over your shoulder.

That’s what “permanent” should really mean.